About Us

28+

Experiences

The Power Behind Your Trust

A Legacy Forged in Excellence

Established in 2007 and formally incorporated as a Private Limited company in 2017, Pavani Power Systems began with a simple yet powerful vision: to become a trusted, homegrown manufacturer of high-quality high-voltage equipment for India’s power sector.

Our journey started with a deep understanding of the critical need for safety and reliability in electrical switchyards. From our early days, we focused on combining rigorous engineering with a customer-first approach. This commitment has allowed us to grow from a ambitious venture into a respected name, supplying essential disconnectors and isolators to utilities and industries across the nation. Our story is not just about products; it’s about building a legacy of trust, one successful project at a time.

Our Commitment to Excellence

Safety First

Protecting your people and assets

Maximum Uptime

Minimizing operational disruptions

Long-Term Reliability

Building systems that last

Our Mission

To strengthen India’s power infrastructure by manufacturing and delivering high-voltage disconnectors and isolators of unparalleled quality, reliability, and safety. We are committed to exceeding customer expectations through continuous innovation, precision engineering, and an unwavering dedication to national and international standards. Our focus is on durability, performance, and total customer satisfaction.

Our Vision

To be a leading global force in the power equipment industry, recognized for technological excellence, unwavering integrity, and our pivotal role in building the sustainable and efficient power networks of tomorrow. We envision a future where Pavani products are synonymous with safety and smart energy solutions, both in India and beyond.

Meet Our Founder

At the helm of Pavani Power Systems is Mr. T. Seshagiri Rao, a leader with extensive technical and commercial expertise in the power sector.

MR. SESHAGIRI RAO THONDANGI

MR. KRISHNA KISHORE THONDANGI

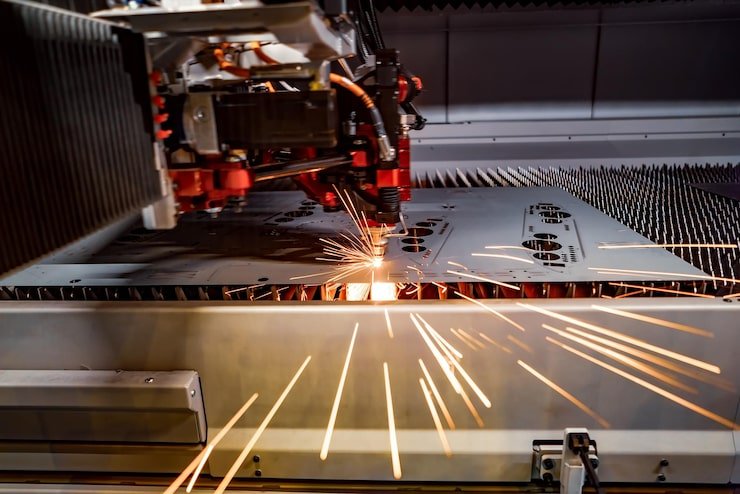

Our State-of-the-Art Facility

Precision Manufacturing Zone

CNC machining centers for micron-level accuracy

Laser cutting technology for clean, precise components

Heavy-duty press brakes for structural forming

- Fabrication

Hot-dip galvanization tanks

Corrosion protection systems

Surface finishing equipment

Why Pavani Power Systems Stands Out

🔧 100% In-House Manufacturing

Unlike many competitors, we maintain complete control over every aspect of production. From design and engineering to fabrication and testing, everything happens under our roof in Hyderabad. This means:

No quality compromises

No communication gaps with subcontractors

Complete accountability

Faster turnaround times

Our Commitment to Sustainability

At Pavani Power Systems, sustainability is built into our operations and products. We implement eco-friendly manufacturing practices—optimizing resources, reducing waste, and using energy-efficient technologies.

Our durable disconnectors and isolators are engineered for longevity, minimizing environmental impact over their lifecycle. By prioritizing quality and efficiency, we support more reliable and sustainable power networks.

We continuously improve our environmental performance, exceeding standards to help build a cleaner, more resilient energy infrastructure for the future.

Our Trusted Clients

Testimonials

FAQ

We manufacture high-voltage disconnectors and isolators for a wide range of applications, from 11kV to 245kV, with current ratings up to 3150 Amps.

Yes, we specialize in customization and design engineering. Our team can modify products to fit your specific site requirements, voltage levels, and configuration needs.

Absolutely. All our products are type tested and certified as per IS 9921 and IEC 62271-102 standards, ensuring global quality and safety compliance.

Lead times vary based on product complexity and order quantity. Generally, we deliver standard products within 4-6 weeks and customized solutions within 6-8 weeks.

We provide complete after-sales support including technical assistance, troubleshooting, and supply of spares and accessories throughout the product lifecycle.

We use premium materials including silver-plated hard-drawn electrolytic copper contacts, non-magnetic stainless steel hardware, and hot-dip galvanized structural components.

Yes, we provide flexible operation options – motorized versions (415V AC or 220V/110V DC) and manual versions with reduction gears or lever operation.

We follow strict quality control processes with rigorous testing at every manufacturing stage, supported by certified laboratory testing and quality assurance protocols.

Yes, we welcome client visits to our state-of-the-art facility. Please contact us to schedule a plant tour and see our manufacturing processes firsthand.

For technical assistance, please email our support team at ppspl.2017@gmail.com or call our technical helpline at +91 99599 35092 Our engineers are ready to help.